Discover Aluminum Foundry and its leading role in today’s aluminum casting

Wiki Article

Comprehending the Various Kinds of Procedures in An Aluminum Foundry for Reliable Manufacturing

In An Aluminum Foundry, numerous casting processes play a critical duty in manufacturing efficiency. Each technique, from sand spreading to pass away casting, provides unique benefits that satisfy details making needs. Recognizing these procedures is essential for optimizing quality and cost. Nonetheless, the option of casting method can substantially affect general result. As foundries discover these choices, they must take into consideration which techniques straighten best with their production goals. What elements will ultimately guide their decisions?Introduction of Aluminum Foundry Processes

Aluminum Foundry processes incorporate a series of specialized strategies aimed at transforming raw Aluminum right into usable parts. These processes typically begin with thawing the Aluminum, where key or scrap Aluminum is heated up till it gets to a liquified state. Once melted, the Aluminum may go through alloying, where certain aspects are contributed to boost its residential properties, such as strength or deterioration resistance.Following melting and alloying, the Aluminum is poured into mold and mildews to produce preferred shapes. Air conditioning and solidification take place, throughout which the product tackles the type of the mold and mildew. After solidification, spreadings are gotten rid of and may require additional handling, including trimming, machining, or surface area treatment to achieve the final specifications. Quality control is indispensable throughout the procedure, making sure that the created elements satisfy market criteria. In general, Aluminum Foundry procedures are important for generating a vast array of lightweight and durable products utilized in different applications.

Sand Casting Methods

A significant part of Aluminum spreadings are created making use of sand casting techniques, which is a versatile method preferred for its capacity to develop complex forms. In this procedure, a mold and mildew is made from sand combined with a binding representative, ensuring it can hold up against the molten Aluminum's temperature level. The pattern, commonly constructed from steel or plastic, is placed in the sand to develop the dental caries for the spreading. After getting rid of the pattern, the mold is loaded with molten Aluminum, which solidifies into the wanted form upon air conditioning.Sand spreading is especially advantageous for low to medium production volumes as a result of its cost-effectiveness and adaptability. Furthermore, it permits easy adjustments of mold and mildew designs, accommodating numerous component geometries. Though it may not attain the dimensional accuracy of other casting techniques, the surface area coating can be enhanced via succeeding machining. In general, sand casting remains a keystone of Aluminum Foundry procedures, guaranteeing varied applications across sectors.

Pass Away Casting Techniques

In the domain name of die spreading methods, two primary procedures stick out: the hot chamber and cold chamber techniques. Each approach offers unique advantages and obstacles, particularly concerning effectiveness and material compatibility. In addition, the selection of die products plays an important function in identifying the overall success and durability of the casting procedure.Warm Chamber Process

Cold Chamber Process

Cold chamber pass away casting stands for a different approach for producing Aluminum parts, especially when handling steels that have higher melting points or when the molten metal is too responsive for hot chamber procedures. In this technique, liquified Aluminum is put into the die from an external ladle, which decreases the danger of contamination and enables better adaptability in alloy choice. The process entails injecting the liquified steel into a cold die making use of a hydraulic piston, making sure specific control over the injection speed and pressure. This technique is useful for producing complicated geometries and attaining high dimensional accuracy. It may need longer cycle times contrasted to warm chamber processes, cool chamber die spreading is vital for details applications in Aluminum foundries.Die Materials Choice

Choosing the suitable die products is essential for optimizing the die casting process and making certain the longevity and performance of the mold and mildews. The most typically utilized materials include tool steel, beryllium-copper, and Aluminum alloys, each offering distinct advantages. Device steel is preferred for its resilience and resistance to wear, making it optimal for high-volume production runs. Aluminum gives superb thermal conductivity, facilitating efficient heat dissipation, while beryllium-copper alloys incorporate toughness and thermal monitoring residential properties, though at a higher price. Elements influencing the choice include the complexity of the part, anticipated manufacturing quantity, and the particular Aluminum alloys being cast. Eventually, the ideal selection of die product can considerably improve performance and decrease general operational prices in Aluminum foundries.Financial Investment Casting Procedures

While different casting techniques exist, investment casting stands out for its capability to produce complex forms with high accuracy and exceptional surface finishes. This procedure includes creating a wax pattern that is coated with a ceramic covering. Once the shell solidifies, the wax is dissolved, leaving a cavity that is loaded with liquified Aluminum.Financial investment casting is specifically advantageous for generating intricate geometries that would certainly be impossible or challenging to achieve with various other techniques. It permits tight resistances, reducing the need for extensive machining post-casting. Furthermore, the smooth surface finish decreases the requirement for secondary procedures, thus boosting efficiency.

This technique is extensively utilized in industries needing comprehensive parts, such as aerospace and medical industries. The flexibility of financial investment casting enables the production of both big and little amounts, making it a beneficial choice in Aluminum factories looking for to satisfy varied manufacturing demands.

Irreversible Mold And Mildew Casting

Long-term mold and mildew spreading is an approach that employs reusable molds to create Aluminum parts, boosting effectiveness in manufacturing. This technique offers numerous advantages, consisting of boosted dimensional precision and surface area finish, making it suitable for different industrial applications. By comprehending its process, benefits, and makes use of, one can appreciate its significance in the Aluminum Foundry market.Refine Summary

Aluminum Foundry processes incorporate numerous methods, one of which is irreversible mold and mildew casting. This method employs recyclable molds, usually made from steel, permitting efficient manufacturing of Aluminum elements. The process begins with preheating the mold to enhance fluidity and minimize defects. Molten Aluminum is after that poured into the mold under gravity or stress, guaranteeing accurate dental filling and reducing air entrapment. As soon as the Aluminum cools down and strengthens, the mold is opened to get the cast component. Permanent mold spreading is recognized for generating premium, dimensionally precise components suitable for different applications. The method is especially beneficial for high-volume manufacturing runs, as it substantially lowers material waste and boosts repeatability in manufacturing processes.Advantages of Technique

Various casting methods exist, permanent mold and mildew casting uses distinct benefits that make it a favored choice for lots of manufacturers. This method enables superior dimensional accuracy and surface area coating, minimizing the need for extensive machining. The recyclable mold and mildews, normally made from metal, enhance manufacturing efficiency by enabling for quick cycle times and lower total material prices. In addition, irreversible mold and mildew spreading promotes improved mechanical residential or commercial properties in the end product because of the regulated air conditioning prices, which cause finer grain frameworks. Additionally, as the process creates less waste compared to sand spreading, it is much more eco pleasant. Overall, these benefits add to cost-effectiveness and high-grade results, making long-term mold and mildew Aluminum Foundry casting a strategic option in the Aluminum Foundry sector.

Applications in Sector

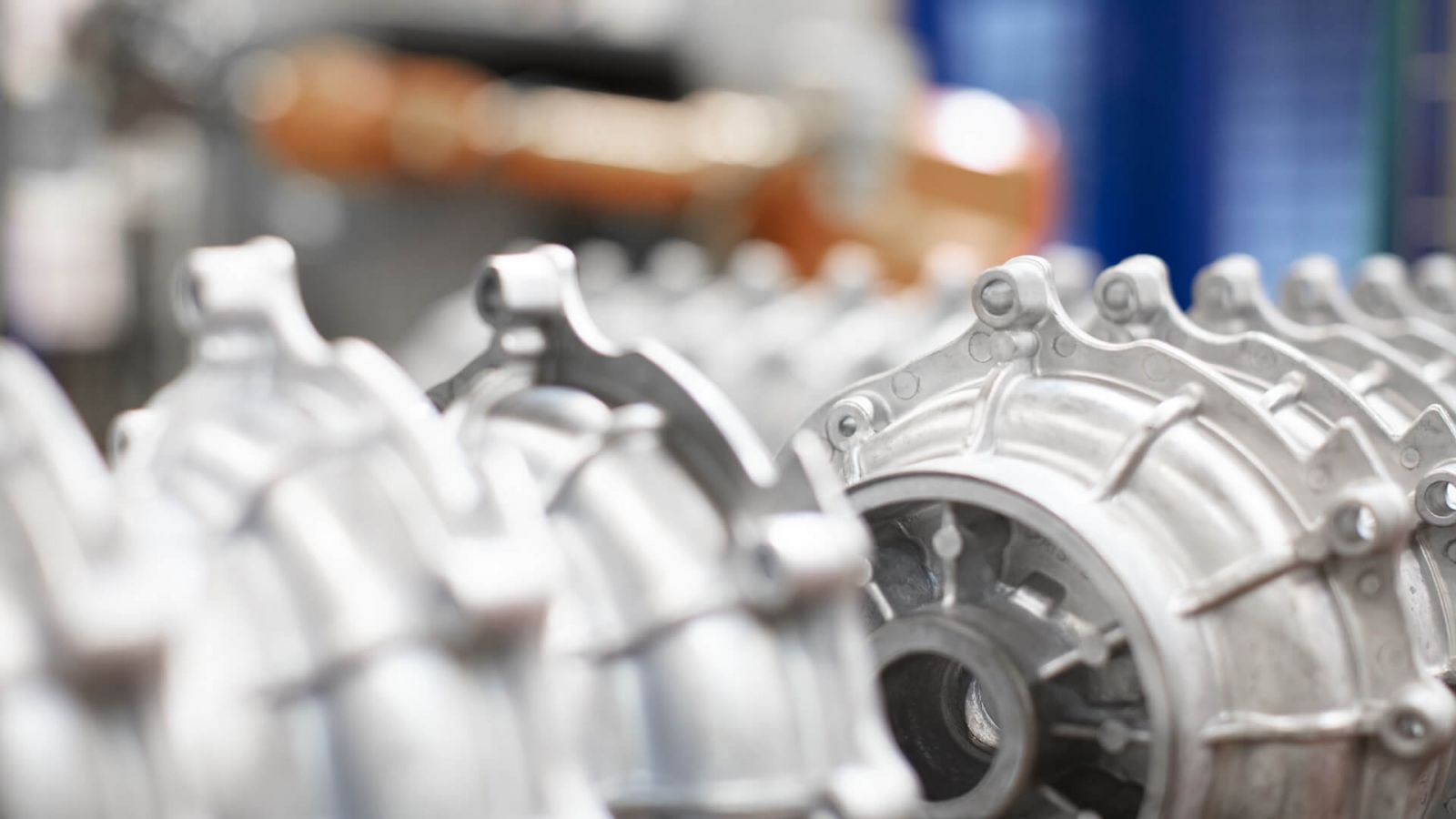

In various industries, permanent mold and mildew spreading plays a necessary duty in producing top quality Aluminum components, particularly where precision and toughness are extremely important - Aluminum Foundry. This approach is extensively made use of in the auto sector for producing engine blocks, transmission housings, and other crucial components that call for precise tolerances and durable performance. In addition, the aerospace sector advantages from irreversible mold casting for elements that have to withstand severe conditions while maintaining light-weight characteristics. In addition, durable goods often use this technique for generating long lasting and cosmetically pleasing items, such as cookware and ornamental components. The ability to accomplish complex geometries and great surface coatings makes irreversible mold casting a recommended option across varied applications, ensuring trusted and effective manufacturing in different commercial contextsMachining and Finishing Operations

Accuracy machining and ending up procedures play an important function in the Aluminum Foundry procedure, guaranteeing that cast parts satisfy rigorous quality and dimensional specifications. These operations entail different methods, such as milling, transforming, boring, and grinding, which are used to fine-tune the surfaces of cast parts. Each method is chosen based upon the particular requirements of the element, including its size, shape, and intended application.Finishing processes, such as anodizing and surface polishing, boost the visual allure and corrosion resistance of Aluminum components. In addition, these procedures help accomplish tighter resistances and smoother surfaces, which are essential for performance in different industrial applications.

High Quality Control in Aluminum Foundries

Quality control in Aluminum foundries is an important part that ensures the integrity and performance of actors products. This process includes organized inspections and testing at numerous phases of manufacturing. Shops apply strenuous top quality checks, consisting of visual assessments, dimensional measurements, and material evaluation, to establish that every cast meets specified requirements.Furthermore, advanced methods such as non-destructive testing (NDT) are employed to detect interior problems that may not show up externally. By checking variables like temperature and alloy composition, factories can preserve excellent production conditions, lowering the likelihood of flaws.

In addition, adherence to industry standards, such as ISO qualifications, enhances a factory's commitment to top quality. Continual training and advancement of employees also play a vital role in cultivating a culture of top quality understanding. Ultimately, efficient quality assurance techniques enhance client contentment and reduce pricey rework and scrap, guaranteeing the Foundry's one-upmanship in the market.

Often Asked Concerns

What Safety And Security Measures Are Required in An Aluminum Foundry?

Precaution in An Aluminum Foundry consist of correct personal protective devices, air flow systems to take care of fumes, fire prevention protocols, routine tools maintenance, worker training on threats, and emergency situation reaction prepares to attend to prospective accidents successfully.Just How Does Recycling Aluminum Affect Foundry Processes?

Reusing Aluminum substantially influences Foundry procedures by decreasing raw product prices, decreasing waste, and lowering energy usage. This green strategy enhances manufacturing performance while advertising sustainability, ultimately benefiting both the setting and the Aluminum market.What Are the Ecological Influences of Aluminum Foundries?

The ecological influences of Aluminum factories include air and water contamination, high energy consumption, and substantial greenhouse gas discharges. These elements add to environment damage and health risks for surrounding areas, requiring improved sustainability techniques.How Do Factories Manage Waste and Emissions?

Shops take care of waste and discharges with different methods, including recycling scrap metal, implementing purification systems, and sticking to environmental policies. These measures intend to minimize ecological impact while keeping functional efficiency and performance.What Is the Function of Automation in Aluminum Foundries?

Automation in Aluminum foundries enhances effectiveness and accuracy. It reduces human error, maximizes manufacturing processes, and lowers labor expenses. By incorporating advanced innovation, shops can enhance item top quality and assurance regular operational performance.Aluminum Foundry procedures include a collection of specialized methods intended at transforming raw Aluminum into functional elements. These processes generally begin with melting the Aluminum, where main or scrap Aluminum is warmed up until it gets to a molten state. The hot chamber procedure is an extremely reliable die casting technique generally made use of for Aluminum alloys. Cold chamber pass away casting stands for an alternate technique for generating Aluminum components, particularly when dealing with steels that have greater melting points or when the molten steel is also responsive for warm chamber processes. Aluminum Foundry. Aluminum Foundry processes include various methods, one of which is irreversible mold casting

Report this wiki page